The earliest known bowed instrument is the Ravanastron of India. It is very similar to the Erhu of China, or the Haegeum of Korea. It has two strings with tuning pegs, and a small round sound body with a membrane as its upper surface. The strings are made of silk.

Other old bowed string instruments are the Rebec, and the Viol, which was the immediate predecessor of the violin.

The violin, viola, cello, and double bass took the place of the instruments of the viol family. At one time, it was believed that they were also directly developed from the viol; except for the double bass, it is now thought that this is not the case.

Instead, it is believed that the mediaeval fiddle, generally referred to its French name, the vielle, was the direct ancestor of the violin family, and that the line of progress passed through the lira da braccio. Unlike the vielle, the lira da braccio often had a strong resemblance to the modern violin, although there were still some differences during most of the lifetime of that instrument; a later specimen, made by Andrea Amati after the violin was already in existence looked almost like a modern violin.

The lira da braccio, pictured at right, was a somewhat specialized instrument.

Its strings were (in one common tuning) tuned an octave below those of the violin, so, like the violin, and unlike the viol, it was tuned in fifths, rather than fourths. That statement, however, is something of an oversimplification, since a violin has four strings, and, most commonly, a lira da braccio has seven. However, those seven strings were in five courses.

A twelve-string guitar is played much the same way as a six-string guitar, as if it only had six strings. That is because it only has six courses; its strings are in six pairs, with the two strings in each pair spaced closely together, so that they would normally, and almost inevitably, be struck and fretted together.

Thus, from the viewpoint of the player, it is really the courses, rather than the strings, that are the basic unit of the instrument.

In the case of the lira da braccio, the five courses are nominally tuned in D, G, d, a, e', with the course tuned in D starting from a point off to the side of the pegboard for the other courses so that its strings do not pass over the fingerboard; it is used as a drone.

The seven strings are tuned to (D, d), (G, g), d, a, e'; thus, both the drone and the course corresponding to the lowest string on a tenor violin are augmented by including both one string at the nominal pitch of the course, and another string an octave higher.

The lira da braccio had an even more specialized relative, the lira da gamba. This instrument was sufficiently obscure that it was only recently rediscovered. A lira da gamba might have twelve or more strings. The bridge was curved, but in a shallow curve, so that when the instrument was played, three or more adjacent strings would usually be bowed at one time.

So that adjacent strings would form chords, this instrument was tuned in a zig-zag fashion; the lowest string would be followed by a string tuned a fifth higher, and then that string would be followed by a string tuned a fourth lower. Then the next string would be a fifth higher than that one, and the pattern would continue.

This arrangement does not quite lead to adjacent strings forming either major chords or minor chords, but the notes they produced were still harmonious, and the instrument was used for playing continuo.

The oldest surviving violins are those made by Andrea Amati of Cremona; at one time, violins made by Gasparo Bertolotti, usually known as Gasparo da Salo, in Brescia were thought to have been older, but recent historical research has overturned this belief.

Another person once mistakenly believed to be the earliest known violin maker was Gasparo Duiffoprugcar; it is now believed that while he made the bowed instruments which preceded the violin, he did not make any actual violins. His last name is a variant spelling of Tiefenbrucker; a different German surname, Tiefenbacher, found its way to Canada in a different variant spelling: Diefenbaker; so he does not belong to the same house as a former Canadian Prime Minister.

In Cremona, Andrea Amati was succeded by his son Girolamo Amati, and then he in turn was succeded by his son Nicolò Amati. Each of them produced violins that were considered to be even better than the violins of their fathers.

It has been generally accepted that Antonio Stradivari was one of the apprentices of Nicolò Amati. However, I am inclined to accept the conjecture offered in the book Stradivari's Genius: Five Violins, One Cello and Three Centuries of Enduring Perfection by Tony Faber, and also echoed by the book Cremona Violins: A Physicist's Quest for the Secrets of Stradivari, by Kameshmar C. Wali, which is about the researches of William F. "Jack" Fry, that Stradivari only worked for Nicolò Amati in the capacity of a woodworker, formerly apprenticed to the woodworker Francesco Pescaroli, to produce decorated violins, and then he later became an apprentice of another violin maker, likely Francesco Ruggeri, based on similarities in their technique of carving the back and belly plates of the violin in order to tune them properly.

The most obvious of those similarities is that, unlike the Amatis, neither of them used a compass in the last stages of graduating the back and the belly: on the violins of the Amatis, and many other Cremonese makers, the mark of a compass point is visible on the inside of the back and belly; this is not the case with Stradivari and Ruggeri. They could, of course, have still used a compass in the earlier stages of removing material.

Francesco Ruggeri and Andrea Guarneri were undoubted apprentices of Nicolò Amati, who also had a son, Girolamo Amati, who was his apprentice as well. To avoid confusion with Nicolò Amati's father, he is often referred to as Hieronymus II. As his father before him, he is considered to have made even better instruments than his father, but unfortunately - at least in so far as his personal circumstances were concerned - he was overshadowed by his contemporary Antonio Stradivari.

Andrea Guarneri was succeeded by his sons Pietro Guarneri and Giussepe Guarneri; the latter had a son also named Giuseppe, famed as Guarnerius del Gesù. Although today a Guarnerius is recognized as a reasonable alternative to a Stradivarius, while Stradivari was successful and wealthy, Giuseppe Guarneri the younger struggled to make a success of his business.

Antonio Stradivari was succeeded by his sons Francesco Stradivari and Omobono Stradivari, who hired Carlo Bergonzi, already an established violin maker, to assist them.

Also, Lorenzo Guadagnini made violins in Stradivarius' workshop, and his son Giovanni Battista Guadagnini is often considered to be the third greatest maker of violins after Stradivarius and Guarnerius.

The old violins of Cremona are held in very high repute, particularly those of Antonio Stradivari; as they were considered the finest violins available at the time they were made as well, about a thousand were made. Those of Guarnerius del Gesu, of Giovanni Guadagnini, and some of those by Carlo Bergonzi, and a select few other early luthiers, are also considered to be comparable, but there are far fewer of those instruments extant, so these violins, and other fine violins from this era of violin making, do not greatly reduce the scarcity of violins of the first rank from what it would be if no other violins had even approached the excellence of a Stradivarius - although the scarcity is such that we must be thankful for each fine violin that exists.

In the case of Antonio Stradivari, it is believed that about 600 of his violins, 60 of his cellos, and 12 of his violas survive.

In the case of Guarneri del Gesù, about 135 of his violins are believed to have survived - and just one cello. His work is considered to be of uneven quality, but some believe that the best of his instruments are better than anything Stradivari made.

In the case of Giovanni Battista Guadagnini, according to some sources, less than 100 of his violins, but more than 45 of his cellos survive. Another source notes that he originally made 403 violins and 39 cellos, as well as 3 double basses and 21 violas; for him to have made 39 cellos, of which 45 survive, of course, indicates a contradiction.

He is considered to be in third place, definitely behind both Stradivari and Guarneri, but many of his instruments are also considered to be fully suitable for concert soloists of the first rank, and of no other maker is this considered to be completely true. (A very few instruments by Carlo Bergonzi are also considered to be in this category - apparently, as I understand it, the ones believed to have been made with bellies left behind by Stradivari.) The tone of a Guadagnini is a bit darker than that of the instruments of the other two makers, but despite this, his instruments excel in one of the most important attributes of a violin of the first rank: they offer a wide palette of timbres to the performer.

Perhaps a little note here is in order: a violin is not a pipe organ with multiple stops, and still less is it a sampling keyboard. However, aside from plucking the strings, or hitting them with the back of the bow, to make different sounds, the position between the fingerboard and the bridge at which one bows the violin determines its sound. Bowing it close to the fingerboard produces a softer sound, and bowing it close to the bridge produces a louder but rough sound.

One can make a violin play louder by pressing harder on the bow; often, this is the way it is done to make the note on the "beat" of a bar a little louder. But the normal way to affect a violin's volume is to draw the bow across it faster, and this is the reason why over the centuries of the development of the violin's bow it became longer.

Usually, the bow is played so that one of its edges is in contact with the string, but it can be drawn flat across the string as well, and this is sometimes recommended for beginners.

All these things, and others, affect the type of sound a violin makes.

Fritz Kreisler is associated with a Bergonzi, and Vanessa-Mae with a Guadagnini.

One name that comes up is that of Domenico Montagnana; he was a luthier in Venice, rather than Cremona or Brescia; while the violins of Stradivarius are praised, among other things, for making it easier (in some ways) for a performer to obtain the best tone from them, those of Montagnana are notoriously difficult to play; yet, they are still highly valued because of the beauty of the tone that can be obtained from them by a sufficiently able performer. Yo-Yo Ma is a performer associated with one.

The earliest surviving Stradivarius was made in 1666, and already bears the stamp of his genius, but his earliest violins were not necessarily superior to those of Nicolò Amati. By 1683, this had changed, and his violins were already superior to any others, but they had not yet reached the peak of their quality, as displayed by the violins of his "golden period" from 1700 to about 1725.

While the violins of Stradivarius were recognized as the best violins available during his lifetime, as the years passed after his death, his reputation passed into obscurity. It was revived by the efforts of Luigi Tarisio in rescuing forgotten Stradivarius violins, and incidentally making a fortune through buying them cheap and selling them dear, and by a concert by Giovanni Battista Viotti in 1782 where he played a Stradivarius violin made in 1709.

Before 1782, it was widely considered that violins such as those made by Jacob Stainer represented the summit of the art of violin making; as Stainer died in 1683, he was a contemporary of the Cremonese violin makers, but he worked in the Tyrol, part of Germany.

At the time Stradivarius made violins, there were some differences in the basic design of a violin compared to the way that violins are made today.

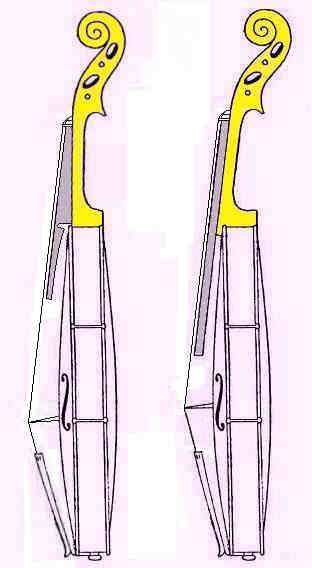

The diagram above shows a Baroque violin on the left, and a modern one on the right. The differences between them are that the neck on a Baroque violin is not tilted back going up; instead, the fingerboard itself is shaped so as to be angled forwards going down at the front, rather than being almost flat and deriving its slope from the neck. As well, the modern neck is somewhat longer, and the modern fingerboard significantly longer.

Also, the bridge is placed lower on the body on the Baroque violin.

While a few Stainer violins have not been converted to the modern form, all surviving Stradivarius violins have been so converted.

Internally, the Baroque violin is different as well; the bass bar is shorter, and the sound post is thinner.

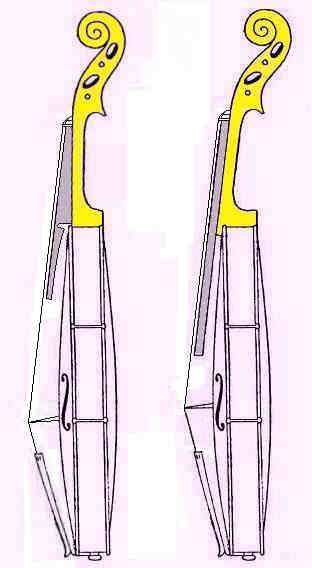

One of the reasons for changing from the Baroque violin is illustrated by the diagram below:

The positions on the strings at which successive notes on the equal-tempered scale are found are indicated by short horizontal lines, and some of them are labelled with the letter name of the note on the G string made at that position.

The red boxes to the left illustrate the different positions of the left hand along the fingerboard, as used in current music, from the first to the eleventh position. As can be seen, most of the increased length of the modern fingerboard is used, and several of the higher positions would be impossible on the shorter Baroque fingerboard.

It can also be seen from the diagram that the higher positions require reaching across the top of the body of the violin.

The diagram above shows several different styles for the bridge.

On the left is a bridge made by Antonio Amati, of Antonio and Hieronymus Amati; the second is one by Niccoló Amati, of the next generation. The third is an outline illustrating the style of bridge made by Antonio Stradivari, and the fourth one, second from the right, is a modern bridge. Finally, in the rightmost position, is the outline of an interesting bridge currently made by Josef Teller OHG; it is their Tourte model (which, of course, bears the name of the inventor of the modern violin bow, a topic I have not yet gotten around to discussing) which is clearly a modern bridge acoustically, while incorporating some visual elements of the baroque bridge.

The book Notice of Antonio Stradivari by Anthony Fétis, to whom the first two parts of the diagram above are due, incorrectly credits the modern bridge design to Stradivari; another old book gives the correct bridge design for Stradivari, but claims the modern bridge design for Guarneri del Gesú. In fact, the modern bridge design came about as part of the re-design of the violin from its Baroque form to its modern form, and thus postdates both Stradivari and Guarneri.

The following image, from an old catalog of a firm selling violins

shows the four basic styles in which their violins were available.

Maggini was a pupil of Gasparo da Salo, and thus he was chosen as the outstanding representative of the Brescian school of violin-making.

Why four different styles?

Even if the best modern makers aren't able to equal the quality of the famous makers of old, the general shape of a violin certainly does have a big influence on its sound. In the case of cheap student violins, this may not be apparent, but it will be even in relatively inexpensive violins of good quality.

Internally, the back plate of a Stradivarius, when tapped in the middle, will make a sound one whole tone higher than the belly plate would. This is also true of most Amati violins. Brescian violins, from Maggini as well as Gasparo da Salo, usually have plate tones that differ only by a semitone in pitch, whereas Guarneri del Gesù made violins with a larger pitch difference than a whole tone.

Also, there are differences in the size, shape, and position of the f-holes between the different violin makers.

Perhaps the most distinctive characteristic of the violins of Stradivarius, and perhaps also the one that makes a Stradivarius "look like a violin", since the Stradivarius pattern is the most common one used in making violins in the present day, is that the size difference between the upper and lower bouts of the violin, although still subtle, is more pronounced than in the Guarnerius pattern or other patterns.

The arching of a violin is also very important to its sound. Of the four patterns shown here, the Amati would have the highest arching, then the Stradivari, then the Guarnerius, and finally the Maggini with the lowest arching.

It is generally believed today that not only are the violins of Stradivarius and the other great Cremonese masters are the best ever made, but that the violins of today, even those made by the best luthiers of today, do not even come close.

There is clearly only one possible explanation for this: space aliens!

In fact, many explanations have been offered. One of the earliest is that Stradivari used a special secret varnish; there is even a legend that his rival Guarneri once arranged a break-in at the Stradivari shop to steal its formula. Another old theory is that violin production led to the extinction of a tree known as the Balsam Fir; but, apparently, this had never actually happened.

Three recent theories that attempt to account for the superior sound of the old Cremonese violins are based on observations that the variation in the density of the wood associated with its grain is less pronounced than in modern wood.

This is variously attributed to the trees growing during a period of low solar activity, resulting in cooler weather, to a bacterial infection that the trees suffered (with a proposal that a particular fungus can be used to more safely produce a similar effect), and, by Dr. Joseph Nagyvary, to a preservative bath given to the wood.

In the case of Dr. Nagyvary, he found that the techniques he tried of applying a preservative bath to wood did not result in the level of mineral content he found in old violins, so instead he uses wood salvaged from the waters of Lake Superior which does have the desired characteristics.

Looking at information about wood preservatives considered safe to use today, most of them were chemicals with long names that doubtless were not available in the time of Antonio Stradivari. The only exception to that I noticed was boric acid, a substance also used in dilute solution as an antiseptic eyewash. It is suitable for use for items that will be used indoors, but water can remove it from wood - so it shouldn't be added prior to "stewing", to be explained below.

In 1938, the physicist Frederick A. Saunders reported that a violin by Franz Josef Koch had a sound confirmed by measurement as closely resembling that of the fine old violins. Franz Josef Koch made violins in Dresden during the 1920s, and had designed them based on his own scientific studies. In particular, he used "a resin that imparted uniform qualities to the wood"; thus, reducing the effect of wood grain has a long history as being considered as an important step in attempting to attain the heights reached by the Cremonese masters.

Another old technique to modify the wood used in a violin was called "stewing": the wood was gently heated in a salt solution. The purpose of this was to accelerate the degradation of hemicellulose in the wood that would take place as the wood ages normally. Hemicellulose absorbs moisture to a greater extent than other parts of wood, so reducing the amount of hemicellulose in wood helps to prevent changes in sound quality, or even cracking of the wood, resulting from changes in humidity. This technique was known and used in old Cremona; there is reason to believe that it was used by Guarneri del Jesu, but there is also reason to believe that it was not used by Antonio Stradivari.

A brochure from Yamaha notes that a technique called A. R. E. (Acoustic Resonance Enhancement), used with their premium Artida series YVN500G and YVN500S violins, accelerates the natural maturing process of the wood, and so other approaches have been attempted to obtain the improvement that time brings to a violin's sound.

A paper on a project in Sweden to replicate old violins using computerized tomography to find their shape, and Computer Numerical Control (CNC) milling to reproduce it, noted that one obstacle which might prevent success is that the wood of the old Cremonese violins had unique properties; not only hemicellulose, but also resins and other items were thoroughly removed from that wood, giving it an excellent strength to weight ratio.

A comparison of new and old violins in another paper found that the average of along-grain and cross-grain strength was the same for ordinary wood and that found in those violins, but the ratio was less unequal. However, one new violin, with a belly made from conventionally treated spruce which had not even been marked as treated in the lumber yard, had characteristics in the old Cremonese region of the graph.

One serious objection to all these schemes is that, since spruce has a more pronounced difference in strength along the grain and across the grain than nearly any other wood, instead of reducing this difference by applying some special formula to the wood, one could more simply have chosen a different wood for the belly of the violin. So if spruce is the best choice, all such schemes are clearly going the wrong way.

In that case, there is one candidate wood that is even more anisotropic than spruce: paulownia.

One published paper stated that Stradivari varnished his violins in three coats:

however, I have read a claim that since that paper came out, its author stated that the methods used to examine the violins in question could not establish the order in which the coats were applied with certainty. However, this particular order still seems the most likely and reasonable one for the ingredients found.

That is, three coats of varnish. One thing that is often ignored is that before applying the first coat of varnish, a ground coat can be, and is likely to be, applied for the purpose of preventing any of the varnish from soaking into the wood, thus significantly mitigating any harmful effects of varnish - even that bugbear, spirit varnish - on the tone of a violin.

Dr. William Fry had to dilute casein wood glue by 50% to make it soak into the wood and work as a stiffening agent: if not diluted, casein glue is one possible ground coat. The commercial product of today, Polyfilla, is shown in one paper as penetrating no further than the first layer of cells in wood, in an electron microscope photograph.

A discussion group on violins gave a formula for a ground coat that would have involved ingredients available to Stradivari:

Make hide glue, such as is used in violin-making. Dilute it with one part of glue to 25 parts of water.

Make a saturated solution of alum.

Add the alum solution to the hide glue carefully, drop by drop, stirring constantly. Stop when the consistency of the mixture changes to that of phlegm.

The final step, making the formula complete, was presented by one Jose Catoira, who credited it to a teacher of lutherie in Newark, New Jersey.

The book by Simone F. Sacconi, I "segreti" di Stradivari (The "Secrets" of Stradivari; the English translation has the same title, but without the quotation marks) denies that Stradivarius himself had any such secret; his superiority to other Cremonese makers of his day was solely due to his own superior craftsmanship.

Since there is a narrow gap between Stradivarius and Guarnerius violins, and the gap between them and other fine early ones (Bergonzi, Guadagnini, and numerous others) is also narrow, but the gap between all of them and later ones is said by many to be a wide gulf in comparison, that could well be entirely true, while yet leaving a lost Cremonese secret that needs to be discovered.

While no "gimmick" would enable an indifferent luthier to make violins the equal of a Stradivarius, if the most experienced and accomplished luthiers of today are unable to approach the excellence of the violins of the Cremonese masters, it is not at all unreasonable to consider the possibility that some unknown factor, such as the lack of the right wood or the right varnish, is standing in their way.

But there is also the null hypothesis: perhaps all the fuss about Stradivarius is just due to hype, and we've all been fooled by Luigi Tarisio and his successors, who have been laughing all the way to the bank.

While some blind listening tests of recent date have lent some support to this notion, I have tended to be inclined to reject out of hand an idea that, on its face, seems to require that almost every single one of the world's greatest violinists is either a liar or a fool. Now that I have learned that the apparent testimony of the Dünnwald graphs, to be discussed below, is not what I thought, I am less sure. As far as I know, no one has tried to devise some way to compare the playing qualities of different violins in an objective manner, and as long as this is the case, despite the recent headlines about blind test results, what science can do to resolve this controversy is limited.

Given that the excellence of a Stradivarius lies more in its playing qualities than its sound, and that to get the best out of even a Stradivarius requires time to become fully familiar with its individual qualities, blind testing under controlled conditions could easily be missing what is important.

But, in any case, objective scientific measurements carried out by Heinrich Dünnwald at one time seemed to me to show that there are very real differences between the classic Cremonese violins and the violins made by the master luthiers of the present time.

A famous graph, reproduced in a number of books and papers, showing the responses of a large number of different violins divided into three groups shows the following:

The frequency response of the old Cremonese violins does not look, from a casual visual inspection, to be too much different from that of inexpensive modern factory-made violins. But there are definite differences.

From about 900 to 1800 Hz, the response of the old Cremonese violins is significantly lower. Excessively prominent resonances in this region tend to make a violin sound "shrill", and so reducing them is an improvement.

|

Since I wrote this, I found from a paper which cited Dünnwald's measurements of one Stradivarius violin that the first peak on the graph was the A0 fundamental resonance of the air inside the violin, and that the graphs were normalized so that the highest peak in a particular frequency region had the value of 25 dB. Thus, it had been a mistake on my part to compare the graphs for the three categories of violins solely on the basis of their general visual appearance. Instead, I needed to shift them so that the height of the peak for A0 was the same for each graph. Once this is done, it becomes apparent that the way to make a violin sound like one by Stradivarius or his most esteemed contemporaries is not, somehow, to implement in wood a filter that reduces response by about 8 dB from 900 to 1800 Hz while having little or no effect outside that range, something difficult enough to achieve with analog electronics, never mind in the design of an acoustic instrument. Instead, what old Cremonese violins have that others don't turns out to be a series of stronger resonances in the range of 1700 to 2500 Hz, and possibly also a couple of stronger ones at around 3000 Hz and 3500 Hz. |

From about 2000 Hz upwards, all the way to 7000 Hz, as far as the measurements were taken, the response of the old Cremonese violins is significantly higher. Stronger response in this area is associated with a "silky" tone, hence a better sound, and with a violin that is able to project its sound better in a concert hall.

The frequency response of the violins by modern luthiers, on the other hand, looks strikingly different from that of cheap factory-made violins.

After about 2500 Hz, the frequency response of a cheap factory-made violin goes downhill, and so does that of an old Cremonese violin, but more slowly. In the case of the ones by fine modern luthiers, though, the frequency response hardly declines at all from 2500 Hz up to at least 6500 Hz.

So the violins by modern luthiers seem to, at least in this respect, have an even better sound, and definitely their sound should project better.

But in the area from 900 Hz to 1800 Hz, where the frequency response of the old Cremonese violins is reduced, that of the violins from fine modern luthiers is not, but is instead even higher than that of cheap factory-made violins.

Incidentally, at least one paper has been published criticizing Dünnwald's method on the basis that it obscures many real differences between violins that can be made evident by bowing their strings rather than hammering their bridges. This, however, does not reduce what I find significant about his findings; it would make questionable any conclusion based on his measurements that some distinction does not exist, but it doesn't diminish the validity of a conclusion that a difference does exist, if the test that found it is limited in its sensitivity.

Here are the conclusions I draw from this:

The differences between the old Cremonese violins and those made today are real, and not due to a placebo effect.

|

Since I wrote this, I have found that in one very important respect, my conclusions are all wet. The distinctive characteristics of the "old Italian" violins in Dünnwald's graphs, in fact, are attainable by modern makers, and have been attained frequently. This does not settle the controversy about whether or not the quality of the old violins is inimitable by makers of the present, but it does mean that Dünnwald had not, as I had thought, provided proof that those violins are at least different, if not necessarily better. Instead, what his graphs show for the "old Italian" violins is the presence of a characteristic known as the "Bridge Hill". It is called by that name because for a time some authorities believed that it was brought about by the bridge of the violin rather than by its body. While more moderate views, recognizing the role of the body of the violin in this, as in other, characteristics of its sound are currently more prevalent, it is true that one of the simplest ways to achieve this characteristic in a violin is to remove a bit of material from one part of the bridge, so as to reduce its ability to transmit high frequencies from the strings to the violin body. |

|

Given, as noted above, that the modern design of the bridge arose as part of the changeover from the baroque violin to the modern violin, it is well that: the bridge-hill is not really a distinguishing characteristic of Cremonese or old Italian violins as against modern ones, as had appeared to be the case initially, following the researches of Dünnwald, since it is not a lost secret as it is found on some modern violins as well, and the bridge-hill is due to characteristics of the body of the violin, and not just the bridge, as had been originally thought when this phenomenon was first discovered and named in 1999. Otherwise, were those two premises true, given that the bridges used on the Cremonese violins must be modern ones, as they are of a design that did not yet exist when those violins were made, the only explanation of their distinctive sound would have to take on the form of a conspiracy theory: they sound better because they are the only ones that get the good bridges. |

However, since the fine luthiers of today are able to make the sound characteristics of their violins differ from those of cheap ones to an even greater extent than the old Cremonese masters did, the suspicion naturally arises that it is not that they aren't making violins that sound like those of Stradivarius because they are unable to, but because they aren't trying to.

Given the high prices that a Stradivarius violin can fetch, that is something that requires an explanation. And the most obvious possible explanation would lead to the conclusion that there is a grain of truth to the very hypothesis that these graphs have disproven - that the Stradivarius phenomenon is due to hype generating a false mystique.

If they aren't trying to make violins as good as those of the Cremonese masters, it could be that they feel that were they to do so, the virtues of their violins would not be recognized, and so they're better off concentrating on improving sonic aspects of their violins that are more obvious during a short demonstration in a violin showroom.

That may not be the only explanation, though; reducing the response in the 900 Hz to 1800 Hz area may be a particularly difficult task, or, at least, it may be particularly difficult to do so without affecting the sound of the violin at other frequencies in such a way as to make it sound "dead". So there could still be a lost secret, even if the secret is not a simple one, but which instead relates to how a violin is tuned by carefully shaving away wood from its top and bottom plates.

Two researchers, who have both been praised by their supporters and advocates as having approached the classic Stradivarius sound, stand out above the rest.

The luthier Carleen Mayley Hutchins, who worked with the physicist Dr. Frederick A. Saunders until his passing in 1963, although she is most famous for proposing a set of eight proportionally-sized instruments to replace the four instruments of the present-day violin family, made an extensive study of plate tuning, showing how and where the thickness of violin plates should be varied to cause their modes of vibration to resemble those of the fine old violins.

The physicist Dr. William F. "Jack" Fry also studied the tuning of violin plates, paying particular attention to how the fibers in the wood affected the behavior of the plates. One of his early basic findings was that the back of the violin should be made thinner on the side opposite the sound post, so that the part of the back around the sound post could move as a unit. In dealing with the portion of the front of the violins between the f-holes, which he found to be relevant to the violin's high-frequency response, he did find it useful to increase the stiffness of the wood across the grain. However, he achieved this without using exotic ingredients; he used normal casein-based wood glue, diluted half-and-half with water to improve penetration.

(This is not necessarily an ideal solution; it works by adding stiffness across the grain, whereas wood preservatives and the other items suggested tend to reduce stiffness with the grain. Since varnishing a violin adds stiffness, and is detrimental to its tone, a question is raised. However, if stiffness were all bad, we would be making the fronts of violins out of rubber, or at least balsa wood; if the wood has more stiffness, then reducing the thickness of the wood will balance that. Since Franz Joseph Koch used a resin to equalize the wood, it is likely that his method also added stiffness rather than reducing it.)

The frequency range that leads to shrillness in a violin, was, according to him, associated with modes in which the bass bar tilts in response to impulses from the bridge. One way to reduce this would be to make the bass bar effectively symmetrical around the foot of the bridge (that is, since it extends further above that point than below it, make it thinner above the bridge so that the product of the amount of wood and its distance from the foot of the bridge, considered as a fulcrum, is balanced), but instead of doing that, he thinned the wood in selected regions of the front of the violin which he referred to as "Stradivari holes", as they were areas which were observed to be thinner on some Stradivarius violins.

In addition, he devised tools which allowed him to continue removing wood from the inside of the top and bottom plates of a violin after it was assembled, by reaching with the tools through the f-holes.

Subsequently, on a visit to the Stradivari Museum in Italy, he saw tools used by Stradivari which he believed were intended to perform a similar function.

I am particularly impressed by that particular finding, as it is indeed obvious that assembling a violin will allow its actual sound qualities to be heard. Of course an experienced luthier can anticipate what a violin will sound like from the sound of the plates, but there might be gaps in that knowledge, while having the actual sound available to hear obviously diminishes the room for uncertainty and error.

If contemporary luthiers have, essentially, all been making violins with one hand tied behind their backs, it's hardly surprising that they have been unable to match the achievements of Stradivarius!

A paper has been published suggesting that the old masters actually did graduate their violins on the outside; this finding was based on measurements that, according to the authors, indicated that the inside surfaces of the violin plates were more regular and symmetrical than the outside surfaces.

I am inclined to be highly skeptical of this claim. However, even in the worst case of that claim being mistaken, the idea of graduating a violin from the outside is still, possibly, very useful.

All right, in the worst case, where graduating a violin from the outside would cause it to have an ugly pitted appearance that would make people reluctant to purchase it, even were it to sound like a Stradivarius, how could doing so be worthwhile?

Well, the problem with graduating the violin plates from the inside was, when we did so, and tapped the plates, we didn't know what sound from those plates was the one we were really looking for, because we didn't have a genuine Stradivarius violin at hand from which we could pop the plates for a listen.

But this way, we now have something almost as good, the ugly-looking violin which we graduated from the outside with our eyes open. We can take its plates off, and use them as the reference for what a plate by itself sounds like!

Of course, there might be some characteristics of the plates that are clearly audible on the finished violin, but difficult to distinguish and match on plates in isolation.

Another problem is that because each piece of wood is unique, one can't make an endless series of identical plates. One can sort the plates one makes, to have plates with a desired pitch difference, but this means that we will have bellies and backs with different pitches. So it may be necessary to have multiple reference plates to cover the different cases.

And this, of course, assumes that the most important factor in making a great violin is giving it the correct pattern of gradation. Many luthiers believe that this is not the case; that instead, violin plates usually have a constant thickness except at the edges, and the important thing is to have suitably aged wood of the highest quality.

The arching still has to be appropriate to the sound one wishes to achieve; as that is an external characteristic of a violin's shape, it is normally determined by one's choice of model.

If one does wish to engage in plate tuning, of course, there are web sites, published papers, and books availalbe which will suggest various schemes of doing so. But no one authority in this matter has been acclaimed as having approached the secret of Stradivari, so one does not know which authority to follow. Graduating a prototype violin from the outside allows one to become one's own authority, and proceed with confidence.

To me, at any rate, this seems like the obvious way to resolve the issue of how one overcomes the inability to hear the finished violin while graduating the plates from which it will be built, by taking an idea which seemed too unconventional to be of use, and applying a little creative thought to that idea so as to find a way to make use of it within the conventional framework which is there for a reason.

When the strings of a violin, resting in grooves on the top of the bridge, move the bridge from side to side, they don't stop moving after they pass the bridge. Not only do they vibrate from the top nut to the bridge, they're also vibrating from the bridge down to the tailpiece. This is why, occasionally on the violin, and more commonly on larger instruments in the violin family, weights are placed on the strings between the bridge and the tailpiece to shift the frequencies of wolf tones away from where they cause trouble.

And both the bridge and the tailpiece transmit vibrations from one string to all the other strings.

The tailpiece isn't attached to the belly of the violin; the tension of the strings holds it up above the belly. Instead, the tailgut, hooked on the tail button, is what holds the tailpiece against the tension of the strings.

And the tail button is round. So it changes a side-to-side force on the tailpiece from the strings into a motion of the tailpiece around the center of the tail button.

Thus, the saddle - the small piece of wood protecting the belly of the violin from the pressure of the tailgut, not the base of the neck of the violin - will also recieve vibrational forces normal (perpendicular) to its surface.

Unlike the belly under the bridge, though, there is no bass bar and sound post combination to prevent the opposed forces from cancelling, and the saddle is above the lower end block of the violin, a solid piece of wood.

While this second bridge, therefore, doesn't have the opportunity to make much sound, possibly if one puts a piece of suitable wood on the violin as the saddle, it might selectively absorb certain frequencies of sound, adjusting the timbre of the violin. Absorb the frequencies from 700 Hz to 1900 Hz well enough, and you just may have found the old Cremonese secret, if Dünnwald's graph is to be believed!

It was noted above that at one point it was claimed that the bellies of Stradivari's violins were made from a kind of spruce called "Balsam fir", which was eventually brought to extinction by violin makers, with no other kind of spruce being its equal.

That story is now considered to be a myth. An interesting footnote is that at one point, Wurlitzer used the term "Balsam fir" as a trademark for the highest-grade violins that they distributed.

There are multiple different kinds of spruce and maple. In Europe, Bosnian maple is still available, and many believe this is what Stradivarius used. As for his spruce, two locations in Europe are most commonly considered candidates to be the source of the fine spruce that he used.

North American woods such as Sitka spruce and curly red maple may be adequate for making the finest violins, as it's not clear that there is that much difference between their properties and those of the European woods in question. And there are various non-traditional woods that might be considered, such as paulownia, mentioned above.

And the willow tree is also a common one. Guarneri used spruce for blocks and linings; I've heard of an experimental violin made from balsa wood; since Stradivari used willow for its lightness, I'm surprised I haven't heard of its use in place of willow for linings and at least some of the blocks. The upper block, as it holds the neck in place, should be made from a strong wood, though, I would think. And the lower block holds the tailpiece. Perhaps an upper and lower block of spruce, corner blocks of willow, and linings of balsa wood?

Ebony is a tropical hardwood which is used in violins, and so here there might be the potential for some concern. For the moment, at least, this has been resolved; while we normally think of ebony as being black in color, as a matter of fact, only a small fraction of the wood from ebony trees is black - but the other wood still has the same physical properties. If that wood is not wasted, then a sustainable harvest will be adequate to supply the demand.

The violin bow is less fortunate.

The wood from which the finest violin bows are made, Pernambuco, comes from a tree that is now classed as an endangered species. No absolutely equivalent substitute has been found; carbon fiber bows do come very close, and so do bows made from Pink Ipê (Handroanthus impetignosus). The minor deficiencies of these two substitutes are different, and thus if there were a practical way to use carbon fiber to reinforce a bow of Ipê so that it would have the liveliness of Ipê and the power of carbon fiber, perhaps the violin world could rest content.

The term "Brazilwood" is used to describe the wood from which less expensive violin bows were made. Apparently, however, that is quite a vague term, and has been applied to inferior quality wood still from the Pernambuco tree, wood from other trees of the genus Cæsalpinia (the Pernambuco tree has recently been reclassified to belong to the genus Paubrasilia, but was formerly known as Cæsalpinia echinata), and various other kinds of wood, such as ironwood and abeille that can be used to make violin bows of a sort.